Pretty much every early model year Saab 9^5 owner is going to have to deal with this one sooner or later. The lever actuating arm on the recirculation control motor snaps off because of dodgy design and improper material selection. This one is a candidate for the “Made by Monkeys” blog at the Design News web site. There are no symptoms except the A/C doesn’t work so well when first starting up a car that’s been sitting in the sun for a while, as the recirc flap defaults to fresh air mode when the lever arm breaks off.

The repair or replacement of this item is fairly easy, as repairs to Saab 9^5 HVAC systems go. Here is a quick outline of what has to be done:

- Remove passenger (LHD cars) footwell cover from left wall;

- Remove under dash cover;

- Remove glove compartment;

- Remove recirculation motor (broken arm usually drops out when motor is removed);

- Repair motor;

- Replace motor and reassemble everything in reverse order.

For early (pre-2001) 9^5’s it’s possible that the motor could be non-operative due to a burned out resistor. If your ACC calibration failed with a code 21 this indicates a failed recirculator motor. Replacement may be your only option on the later cars as mine (MY2001) has the motor sonic welded together, there’s no practical way to disassemble it to replace the failed 18 ohm resistor that tends to happen on the early cars. It’s easy enough to test the motor on the bench with a 12V power supply. Apply voltage one way, then reverse the polarity to move the motor back in the other direction. You will need to do this in any case in order to move the shaft to a middle position if you effect the repair I listed below. A replacement actuator arm part (part number 4869426) can be found at www.gmpartsdepartment.com for about $USD20 last time I checked. Since this didn’t look like too much trouble to frig a repair, and the force needed to move the recirculation flap is pretty small, I decided to try a fix.

Detailed Repair Instructions

Remove passenger side footwell cover by removing 3 plastic anchor pins:

WARNING: don’t try to forcefully pull out the 3 clips! They come out really easy if you know the secret: use a small screwdriver and push in the center pin about 1/8″. It should click and stop. At that point the clip is released and should just pull right out. For reassembly, push the center pin out from the inside of the clip. Insert the clip and pin back into its hole, and depress the center pin flush in order to lock in the clip. (Sure wish we had these on the Saab 9000!) Remove the cover, and note the locating pin behind the upper plastic clip.

Remove under dash cover by removing 4 T25 screws as shown below:

Remove the glove compartment by removing 3 screws at the bottom:

Then remove the three screws behind the door at the top:

Gently pull the glove compartment forward, and disconnect the two leads for the glove compartment light and the small hose for the cooling air. Remove the glove compartment from the car, and now you should have full access to the right side of the air box.

Disconnect the electrical connector for the recirculation motor, and remove the connector from the bracket. Remove the two 6mm/Philips screws holding the motor in (the left screw is deep inside the boss shown, use a #2 Philips on this one) and remove the motor. Replace the broken actuator arm and reassemble. Or, if you are cheap like me, repair the arm and then reassemble.

I made up a little piece of 0.025″ thick aluminum and epoxied it to the motor and broken shaft:

I used a clear epoxy. JB Weld would probably work as well. Shim the broken arm in place until the epoxy sets, then remove the bits while you still can to keep the epoxy from creating a mess by sticking to the shims, then be patient and let the epoxy fully harden. To ease reassembly, use the power supply to run the shaft to its full CCW position (this is the default position of the recirculator flap).

Update, July 2012:

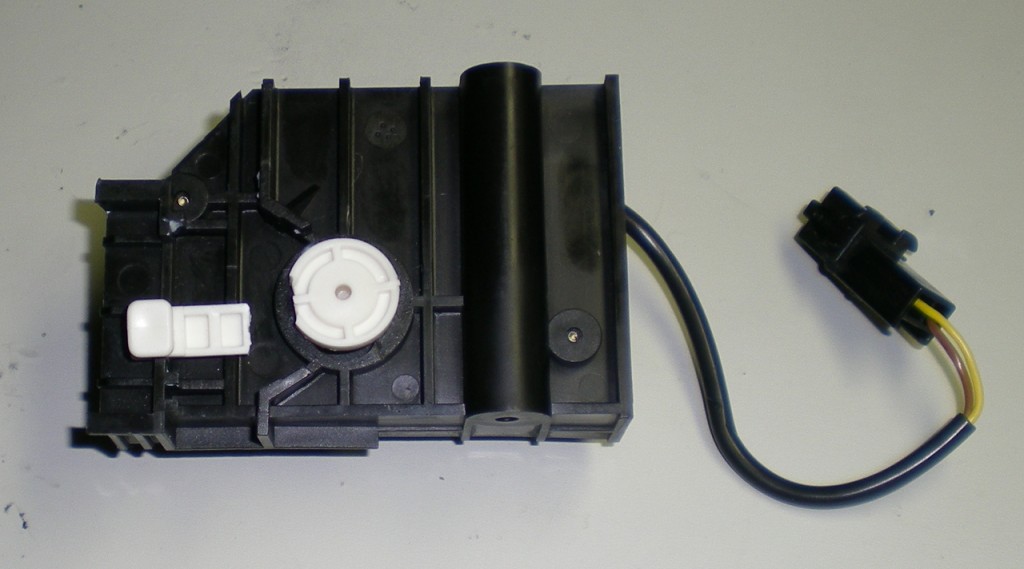

Seems the epoxy didn’t stick too well to the nylon material the arm is made out of. So rather than a chemical solution this time I took a mechanical approach. I had some miniature “Plastite” screws I’d used on a recent project so just used some of these, along with a little more metal bending, to secure the arm to the motor. McMaster-Carr has them. You’ll also need a T-5 Torx® driver and a 1.25mm drill bit to complete the work. So far with two road trips today in 90°+ weather everything is working fine. This is what the latest repair looks like:

Recirculator actuator servo, second repair attempt

Have fun!